2021 High quality Ultrasonic Thickness Measurement Gauge - TM510FNplus Coating thickness gauge – TMTeck

2021 High quality Ultrasonic Thickness Measurement Gauge - TM510FNplus Coating thickness gauge – TMTeck Detail:

● 2 Measuring modes: continuous/single

● 2 Shutdown modes: manual/automatic

●Wide measuring range with 5 probes available (next page)

●Direct testing mode and block statistics mode (APPL/BATCH)

●Can connect with printer to out of statistical values

●Dataview to connect with PC with USB 2.0 port

●500 datas can be stored

Main features

Can use various probe (F400, F1, F1/90 °, F10, N1, N400, etc.) measurement;

Three calibration methods: one point calibration, two point calibration, the basic calibration;

Display resolution: 0.1 um (measuring range of less than 100 um)

1μ m (range greater than 100 u m)

Have five statistics, data storage 500

There are two working methods: direct ways and means of group

There are two measurements: continuous measurement and a single measurement

There are two shutdown: manual and automatic shutdown shutdown

Can be set Bound: The gauge of the measured value can be automatic alarm and a number of measurements available on the histogram value analysis;

Deleted features: the gross error and error settings can be deleted;

Printing: Print Measurement measurement, statistics, gauges, histogram

A music tone in the operation carried out at any time tips

A power supply under-voltage direct function

An error function

And printers, computer communications (communications software operating environment for the Window operating system) connectivity.

Technical Specifications:

| Measuring range | 0-1250µ with standard probe F1.N1 (10.000mm max) |

| Probes available | 5 probes available for F (ferrous: on steel/iron) and N (non-ferrous metals) |

| Tolerance | F1:±(1µ+3%H) N1.±(1.5µ+3% H)H: actual thickness tested |

| Resolution | Alphanumeric with 4 large digits |

| Operation language | English |

| Standards | DIN, ISO, ASTM,BS |

| Min. measuring area | F1:(standard probe) |

| Min. curvature radius | convex:3mm, concave:50mm |

| Min. substratethickness | type F: 0.5mm, type N: 50mm |

| Calibration | Zero and foil calibration |

| Statistics | Number of measurements, mean, standard deviation,maximum and minimum of 3000readings |

| Data memory | 500 measuring data |

| Limits | Adjustable with acoustic alarm |

| Interface | USB 2.0 |

| Operating temperature | 0-40℃ |

| power supply | AA size 1.5V |

| Dimensions | 125*67*31mm (main unit) |

| Weight | 345.g |

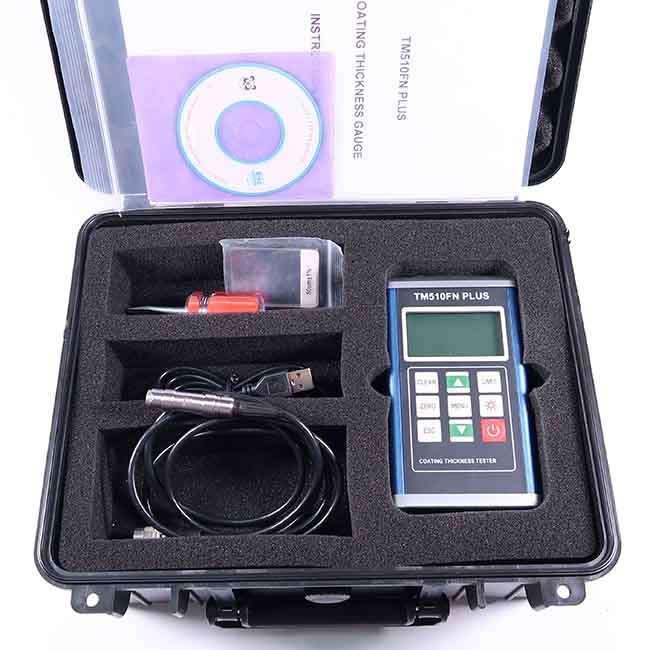

Standard Delivery

| · Main unit | 1 |

| · Probe F1 or N1 | 1 |

| · Calibration foils | 5 |

| · Instruction manual | 1 |

| · Cetificate | 1 |

| · Warranty card | 1 |

| · Carrying case | 1 |

| Communication cable | 1 |

| PC software Dataview | 1 |

Optional accessories

●5 probes for different applications

●Calibration foils in various thickness

Type F probe:

|

Probe |

F400 |

F1 |

F1/90° |

F10 |

|||

|

Measuring Principle |

Magnetic method |

||||||

|

Measuring range(mm) |

0~400um |

0~1250 um |

0~10000 |

||||

|

Min resolution(mm) |

0.1 |

0.1 |

10 |

||||

|

Tolerance |

One-point calibration (mm) |

±(2%H+0.7) |

±(2%H+1) |

±(2%H+10) |

|||

|

Two-point calibration (mm) |

±(1%H+0.7) |

±((1%H+1) |

±(1%H+10) |

||||

|

Minimum radius of curvature (convex) (mm) |

1 |

1.5 |

flat |

10 |

|||

|

Minimum measuring area(mm) |

F3 |

F7 |

F7 |

F40 |

|||

|

Minimum thickness of base material(mm) |

0.2 |

0.5 |

0.5 |

2 |

|||

Type N probe

| Probe | N400 |

N1 |

CN02 |

|

| Measuring Principle |

Eddy current method |

|||

| Measuring range (mm) |

0~400 |

0~1250 |

10~200 |

|

| Min resolution(mm) |

0.1 |

0.1 |

1 |

|

| Tolerance | One-point calibration (mm) |

±(2%H+0.7) |

±(2%H+1.5) |

±(2%H+1) |

| Two-point calibration (mm) | ±(1%H+0.7) | ±(1%H+1.5) |

——– |

|

| Minimum radius of curvature (convex) (mm) |

1.5 |

3 |

flat |

|

| Minimum measuring area(mm) |

F4 |

F5 |

F7 |

|

| Minimum thickness of base material(mm) |

0.3 |

0.3 |

0 |

|

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand abroad business" is our progress strategy for 2021 High quality Ultrasonic Thickness Measurement Gauge - TM510FNplus Coating thickness gauge – TMTeck , The product will supply to all over the world, such as: Sri Lanka, Juventus, Paraguay, We expect to deliver merchandise and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products and solutions all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!