Best-Selling Vickers Hardness Testing Machine - Leeb hardness tester THL280 Plus – TMTeck

Best-Selling Vickers Hardness Testing Machine - Leeb hardness tester THL280 Plus – TMTeck Detail:

Features

LCD display of 128×64 matrix with back-light, showing all functions and parameters.

Converts to all common hardness scales (HV,HB,HRC,HRB,HRA,HS).

English displaying and easy and convenient menu operation.

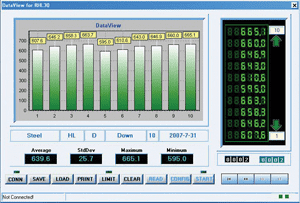

Powerful PC Software available and USB 2.0 interface & with the USB Protective Membrane.

7 types of Impact Device optional, which don’t need to be recalibrated when changing them.

Memory of 600 groups data(impact times:32~1).Lower limit setting and sound alarm.

Material of “cast steel” is added; HB values can be read out directly when D/DC impact device is used to measure “cast steel” work piece.

Printer be separated from main unit and copies of testing results can be printed as required.

AA battery can easy change and transport.

Inbuilt function of Software Calibration.

Specifications

| Hardness scale | HL, HB, HRB, HRC, HRA, HV, HS |

| Memory | 48~600 groups (impact times: 32~1) |

| Measuring range | HLD(170~960)See below table 1 and table 2 |

| Accuracy | ±4HLD (760±30HLD) error of displayed value |

| 4HLD (760±30HLD) repeatability of displayed value | |

| Standard Impact Device | D |

| Optional Impact Devices | DC/D+15/G/C/DL |

| Max. Workpiece Hardness | 996HV(For Impact Devices D/DC/DL/D+15/C) |

| 646HB(For Impact Device G) | |

| Min. Radius of Workpiece | Rmin = 50mm (with special support ring Rmin= 10mm) |

| Min. Workpiece weight | 2~5kg on stable support |

| Min. Workpiece thickness | 5mm (Impact Devices D/DC/DL/D+15) |

| 1mm (Impact Device C) | |

| 10mm (Impact Device G) | |

| Min. thickness of hardened surface | 0.8mm |

| Power | AA battery |

| Continuous Working time | approx. 100 h (no back light off) |

| Charging time | 2-3.5 h |

| Operating temperature | 0~40℃ |

| Relative humidity | ≤90% |

| Overall dimensions | 125*67*31mm (main unit) |

Datapro for Hardness tester THL280 PLUS

Standard Configuration

|

Seq |

Name |

Qty |

Remark |

|

1 |

Main Unit |

1 |

Standard configuration |

|

2 |

Impact Device Type D |

1 |

Standard configuration |

|

3 |

Test Block Type D |

1 |

Standard configuration |

|

4 |

Cleaning Brush |

1 |

Standard configuration |

|

5 |

Supporting Ring |

1 |

Standard configuration |

|

6 |

Communication Cable |

1 |

Standard configuration |

|

7 |

Manual |

1 |

Standard configuration |

|

8 |

Carrying Case |

1 |

Standard configuration |

|

9 |

DataPro Software(USB) |

1 |

Standard configuration |

|

10 |

Battery Case Tool |

1 |

Standard configuration |

|

11 |

Mini-printer |

1 |

Optional configuration |

Product detail pictures:

Related Product Guide:

abide by the contract", conforms towards the market requirement, joins during the market competition by its good quality likewise as provides additional comprehensive and great services for customers to let them turn out to be big winner. The pursue of your enterprise, is the clients' fulfillment for Best-Selling Vickers Hardness Testing Machine - Leeb hardness tester THL280 Plus – TMTeck , The product will supply to all over the world, such as: Sevilla, Jeddah, Norway, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.