China OEM Metallurgical Microscopes - ZXQ-1 Automatic Metallographic Sample Mounting Press – TMTeck

China OEM Metallurgical Microscopes - ZXQ-1 Automatic Metallographic Sample Mounting Press – TMTeck Detail:

Automatic Metallographic Sample Mounting Press is used to mosaic small specimens, specimens in irregular shapes, or specimens which are not easy to take up. It is the preceding process before grinding and polishing metallographic or rock specimens.

The mosaic operation serves to facilitate the grinding and polishing operations of the specimens and the routine observation of the composition of the material under the metallographic microscope.

The machine is heated, and intensified with pressure automatically. After the formation of the specimen under pressure, it stops the operation and discharges the pressure also in an automatical way.

With another press of the knob, the machine automatically turns up the specimen, which may be taken away. Note: It is only for the hot and solid materials (such as jade powder and bakelite powder) with the temperature automatically regulated and controlled.

Technical parameters :

Specification of Samples: φ22mm, φ30mm, φ45mm

Heater: 220V 650W

Total Electric Power: 1000W

Dimensions: 380×350×420mm

Net Weight: 50Kg

ZXQ-5 HOT Metallographic Inlaying

The sample inlaying machine can inlay improper samples in shape or size to meet the following sampling steps, to obtain required inspection surface, or to protect edges or surface defects caused in the course of sample preparation. In modern metallographic labs, semi-automatic or automatic grinding/polishing machines have a certain requirement in sample size, so the samples must be inlayed. The sample inlaying machine is an indispensable equipment in the metallographic labs.

The machine is an automatic metallographic sample inlaying machine with cooling function, applicable to thermal inlaying of all materials (thermoset and thermoplasticity). Set inlaying parameters such as heating temperature, heat holding time, acting force, etc., put sample and inlaying materials, close the gland, press down the button, and then the machine can inlay automatically without a watchman. The machines may change four kinds of dies at will according to various requirements of samples, and also can press two samples simultaneously.

Technical Parameters

1. Specification of Die: φ22mmφ30mmφ45mm

2. Power Supply: 220V 50HZ

3. Max. Power Consumption: 1600W

4. Setting of System Pressure: 0~2MPa (setting of sampling pressure: 0~72MPa)

5. Setting of Temperature: 0~300℃

6. Setting of Heat Holding Time: 0~99 min. 99 sec.

7. Dimensions: 615mm×510mm×500mm

8. Weight: 110kg

9. Type of Cooling: water-cooled

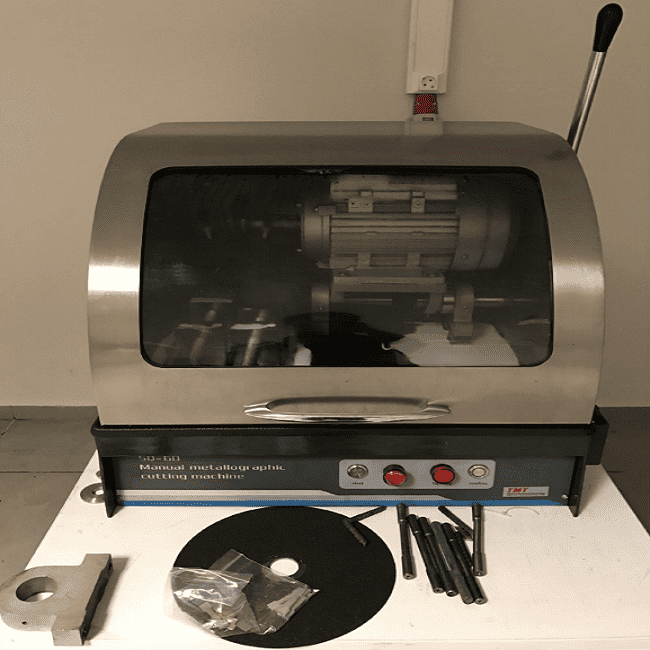

Product detail pictures:

Related Product Guide:

Our products are broadly identified and trustworthy by people and may meet continually modifying financial and social requires of China OEM Metallurgical Microscopes - ZXQ-1 Automatic Metallographic Sample Mounting Press – TMTeck , The product will supply to all over the world, such as: Ghana, Uruguay, Liverpool, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!