High precision hardness tester THL600

High precision hardness tester THL600

Features

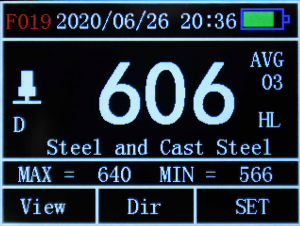

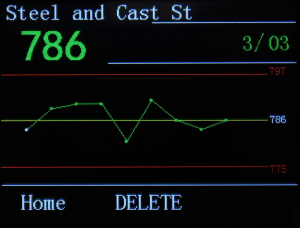

Color display of 3inch screen showing all functions and parameters.

Converts to all common hardness scales (HV,HB, HRC,HRB,HRA,HS).

English displaying and easy and convenient menu operation.

Powerful PC Software available and USB 2.0 interface & with the USB Protective Membrane.

7 types of Impact Device optional, which don't need to be recalibrated when changing them.

Memory of 1200 groups data(impact times:32~1).Lower limit setting and sound alarm.

Material of “cast steel” is added; HB values can be read out directly when D/DC impact device is used to measure “cast steel” work piece.

Printer be separated from main unit and copies of testing results can be printed as required.

AA battery can easy change and transport.

Inbuilt function of Software Calibration.

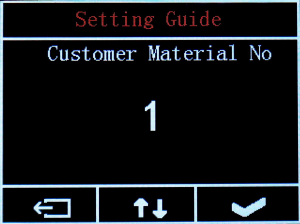

With user-defined material curve function, for special materials such as forged steel, rolled steel, alloy steel or special processing metal materials, users can customize the measurement curve according to the actual measurement.

THL600 with auto direction can make test easy.

Standard according including : national standard: GB/T 17394.1-2014; GB/T1172-1999

EU standard: DIN 50156-2007

ASTM standard:ASTM A956(2012)

THL600 custom material curve function

Due to the different alloy ratios of alloy materials or due to special hot and cold processing techniques, the elastic modulus of some metal materials is different from that of the same kind of ordinary materials, which results in the testing of such materials, whether it is the national standard conversion table or the European standard. The conversion table cannot accurately convert the different hardness systems. The function of the custom material curve provides a means to adjust the conversion table according to the actual situation, which is conducive to expanding the applicability and accuracy of the instrument product.

Big Word and colorful Screen Customer Curve

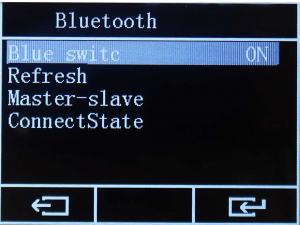

Graphing Display Bluetooth Printer

Specifications

| Hardness scale | HL, HB, HRB, HRC, HRA, HV, HS |

| Memory | 48~600 groups (impact times: 32~1) |

| Measuring range | HLD(170~960)See below table 1 and table 2 |

| Accuracy | ±4HLD (760±30HLD) error of displayed value |

| 4HLD (760±30HLD) repeatability of displayed value | |

| Standard Impact Device | D |

| Optional Impact Devices | DC/D+15/G/C/DL/E |

| Max. Workpiece Hardness | 996HV(For Impact Devices D/DC/DL/D+15/C) |

| 646HB(For Impact Device G) | |

| Min. Radius of Workpiece | Rmin = 50mm (with special support ring Rmin= 10mm) |

| Min. Workpiece weight | 2~5kg on stable support |

| Min. Workpiece thickness | 5mm (Impact Devices D/DC/DL/D+15) |

| 1mm (Impact Device C) | |

| 10mm (Impact Device G) | |

| Min. thickness of hardened surface | 0.8mm |

| Power | AA battery |

| Continuous Working time | approx. 100 h (no back light off) |

| Operating temperature | 0~40℃ |

| Relative humidity | ≤90% |

| Overall dimensions | 120*60*31mm (main unit) |

Standard Configuration

|

Seq |

Name |

Qty |

Remark |

|

1 |

Main Unit |

1 |

Standard configuration |

|

2 |

Impact Device Type D |

1 |

Standard configuration |

|

3 |

Test Block Type D |

1 |

Standard configuration |

|

4 |

Cleaning Brush |

1 |

Standard configuration |

|

5 |

Supporting Ring |

1 |

Standard configuration |

|

6 |

Communication Cable |

1 |

Standard configuration |

|

7 |

Manual |

1 |

Standard configuration |

|

8 |

Carrying Case |

1 |

Standard configuration |

|

9 |

DataPro Software(USB) |

1 |

Standard configuration |

|

11 |

Bluetooth Printer |

1 |

Optional configuration |