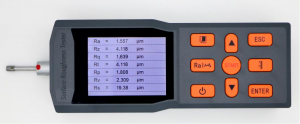

Manufacturer for Tr200 Roughness Tester - TMTECK Handheld Surface roughness tester TMR201 – TMTeck

Manufacturer for Tr200 Roughness Tester - TMTECK Handheld Surface roughness tester TMR201 – TMTeck Detail:

Introduction

TMR201 Hand-held Surface Roughness Tester is a new generation of Surface Roughness Tester Series. It features high accuracy, wide application, simple operation, portability and stable performance. The tester is widely used in measuring the surface roughness of various metals and non-metals.

Application

1. Machining process control: grinding, turning, milling, honing, polishing, etc.

2. Heavy industry: shipbuilding, aerospace, pipeline, steel plate

3. Aerospace: turbine blades, turbine shafts, wings and other composite materials.

4. Others: printing roller, floor, and glass.

Measuring Principle

By using wear-resistant diamond needle parts and precise motor drive structure, the sensor walks at the absolute linear movement specified by the standard, and walks at the correct horizontal distance.When the low test force tentacles across the wave peak and wave valley, the high precision inductive bridge circuits will detect their vertical displacement through modulation, amplification and phase sensitive detection wave. The sensitivity can up to nanoscale level.The voltage signal corresponding to the roughness is transmitted to a high computing power ARM + DSP processor, using a standardized algorithm to calculate the surface roughness parameters instantly.

TECHNICAL SPECIFICATIONS

|

Application |

Measure surface roughness |

|

|

Type |

Portable |

|

| Measuring range | Z-axis(vertical) |

Upper limit:200μm; |

|

Lower limit:0.010μm; |

||

| X-axis(horizontal) |

17.5mm(0.71inch); |

|

| Circuit resolution | Z-axis(vertical) |

0.002μm±20μm; |

|

0.004μm±40μm; |

||

|

0.008μm±80μm; |

||

| Parameters | Ra Rz Rq Rt; | |

| Rp Rv R3z R3y Rz(JIS); | ||

| Rs Rsk Rku Rsm Rmr; | ||

| Standards | ISO4287; ANSI B46.1; | |

| DIN4768; JIS B601; | ||

| Display | 320*240 LCD color display. Display TP curve, roughness filter waveform; | |

|

Communication |

USB interface |

|

|

Storage |

100 sets of data |

|

|

Filter |

RC,PC-RC,Gauss,D-P; |

|

|

Sampling Length (mm)(lr) |

0.25,0.8,2.5; |

|

|

Evaluation Length (mm)(ln) |

Ln=lr×n n=1~5; |

|

|

Sensor |

Measurement principle |

Electromagnetic inductance; |

|

Stylus |

Natural diamond, 90° tip radius, radius of stylus point 5μm; |

|

|

Test force |

<4mN; |

|

|

Skid |

Cemented carbide, drive direction radius 40mm; |

|

|

Drive speed |

lr=0.25 ,Vt=0.135mm/S; |

|

|

lr=0.8 , Vt=0.5mm/S; |

||

|

lr=2.5 , Vt=1mm/S; |

||

|

On returning Vt=1mm/S; |

||

|

Display resolution ratio |

0.001μm; |

|

|

Display error |

±(5nm+0.1A) |

|

|

Repeatability of displayed value |

≤3%; |

|

|

Residual profile |

≤0.01μm; |

|

|

Battery |

3.7V rechargeable Li-on battery |

|

Features

.High-speed ARM+DSP processor with low power consumption, strong computing power and fast calculation speed, and the result will be available within 1 second after the travel.No need to wait.

.Collect thousands of datas in the distance of travel to accurately reproduce the surface of the workpiece.

.Precise digital filter. Ensure machine repeatability is less than 2%.

.10% accuracy error in line with the national standard.

.Adapt to high temperature, high humidity, high vibration working environment.

.The test results can be traced back to the roughness parameters of the national benchmark.

.Diamond touch needle, strong and durable.

.Unique software processing. Start the test immediately, no need to wait.

.Precision inductive bridge sensor with resolution up to nanometer level.

.Low measuring force sensor in line with national standards has low impact on user workpiece.

Characteristics

.320*240 Highlight color LCD screen, exquisite display of roughness waveform.

.320*240 Highlight color LCD screen.Adapt to the low-light workshop environment

.Simple nine-button operation. clear and simple.

.Simple and intuitive menu design is convenient to set roughness parameters.

.Lithium battery power supply with USB charging. Charge it once, users can use it thousands of times.

.Very low motor sound. Strong operating comfort.

.Simple software calibration. Errors can be quickly corrected on site.

.Up to 26 roughness parameters.

.With the USB communication function, users can upload the data to the computer and PLC.

.100 sets of test data storage.

Package List

|

Part |

Quantity |

Note |

|

|

Standard |

Host |

1 |

|

|

Sensor |

1 |

Precision component |

|

|

Adjustable support |

1 |

||

|

Sensor protector |

1 |

||

|

5V ac power adapter |

1 |

||

|

USB cable |

1 |

||

|

Operating manual |

1 |

||

|

Qualified certificate |

1 |

||

|

Warranty card |

1 |

||

|

Packing list |

1 |

||

|

Equipment case |

1 |

||

|

Optional |

Standard sample plate |

||

|

Glass support |

|||

|

Curve sensor |

|||

|

Pinhole sensor |

|||

|

Quirk sensor |

Product detail pictures:

Related Product Guide:

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Manufacturer for Tr200 Roughness Tester - TMTECK Handheld Surface roughness tester TMR201 – TMTeck , The product will supply to all over the world, such as: Oslo, Egypt, India, It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We provide wholesale prices on all our quality parts so you are guaranteed greater savings.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.