TMBRV-250AT Intelligent automatic Brovey hardness tester

Product Introduction

1.Modern minimalist design

2.Various Rockwell scales, HVT, HBT optional

3.Full automatic, high precision force sensor, closed loop force feedback control system

4.Worktable automatic lifting, anti-collision detection device and Z axis rollback system

5.Automatic application of initial test force and main test force.

6.The table automatically rises, the sample stops rising after touching the indenter, automatically loads, automatically unloads, and automatically measures the hardness value.

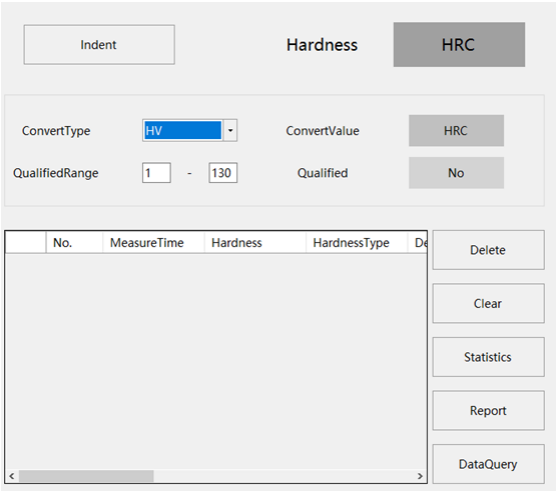

7.Touch screen interface, the operator is convenient, directly select the hardness scale, the force value is automatically changed.

8.Powerful data processing function, including: HR, HB, HV and other hardness system conversion, qualified range setting, over limit automatic alarm, can input tester, sample name and other information

9.According to the standard hardness block, each hardness scale is divided into high, medium and low three sections for automatic correction.

10.The test force can be automatically corrected by the standard dynamometer.

11.Ultra High precision X/Y table (optional)

Repeated positioning accuracy :3 micron stroke up to 200mm

12.The database processing function is powerful, including: HR, HB, HV and other hardness system conversion, set the qualified range, over limit automatic alarm, can input tester, sample name and other information. The measurement parameters and data are automatically saved to the database.

13.Qr code scanning, cloud storage of detection data, data analysis, remote diagnosis and upgrade

Mobile phones and computers display real-time detection data and historical data

14. Automatically calculate hardness value uncertainty (optional)

15. Automatic generation of documents required for CNAS review (optional)

16. Remote diagnosis and upgrade (optional)

I、Technical parameters:

| Model number | TMBRV-250AT |

| Hardness scale | Brinell, Vickers, Rockwell, Surface Rockwell |

| Force value | 5 ~ 250kgf |

| Brinell scale | HBW1/ : 5, 10, 30kgf

HBW2.5/ : 6.25, 15.625, 31.25, 62.5, 187.5kgf HBW5/ : 25, 62.5, 125, 250kgf HBW10/ : 100, 250kgf |

| Rockwell scale | A, B, C, D, E, F, G, H, K, L, M, P, R, S, V

15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W 15X, 30X, 45X, 15Y, 30Y, 45Y |

| Vickers scale | HV5, HV10, HV20, HV30, HV50, HV100, HV120kgf |

| Measuring System | Automatic measurement |

| Objective magnification | 2.5X, 5X (optional 10X, 20X) |

| Camera | 500 pixels |

| Data display | Computer display data |

| Tests | Automatic loading, holding and unloading |

| indenter | Rockwell diamond: 120°

Rockwell ball indenter: 1/16 “, Vickers diamond: 136° Brinell ball indenter: 1mm, 2.5mm, 5mm, 10mm (Rockwell ball indenter option 1/8 “, 1/4 “, 1/2 “) |

| Lighting system | LED |

| enforce standards | GB/T230, GB/T231, GB/T4340, JJG144-1999, GB/T18449, ISO 6508, ASTM E10, ASTM E92, ASTM E18, ASTM E384, ASTM E103 |

| Total experimental force retention time | 1-99 seconds |

| Sample Specifications | Maximum height of sample: 220mm

Indent-outer wall distance (throat) :200mm Cylindrical specimen: The minimum diameter of cylindrical specimen on the outer surface is 4mm; |

| Maximum test height | Rockwell: 220, Brinell: 150mm |

| Distance from center of indenter to outer wall | 200mm |

| Size | 500*260*750mm |

| Weight | About 70Kg |

| Power supply | AC220V+5%, 50-60Hz |

Test Software

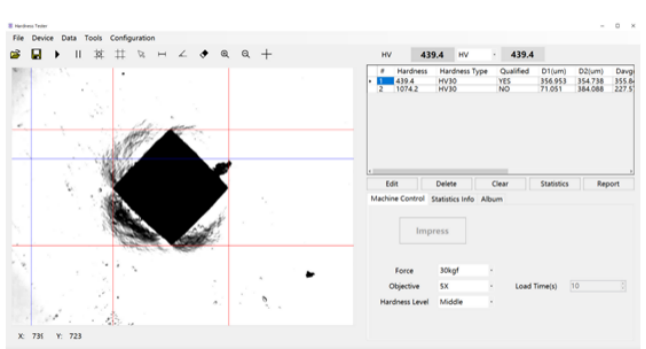

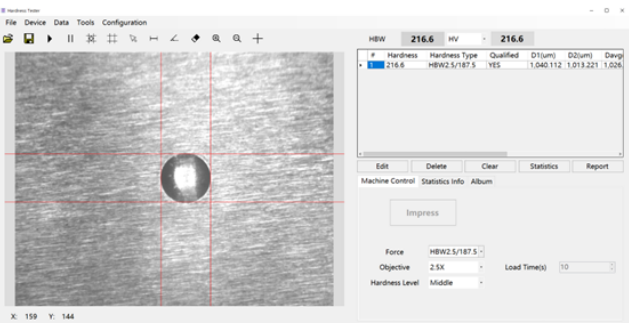

1.5 megapixel camera with clear images, indentation measurement automatic/manual measurement

2.Calibration using micrometer or hardness block calibration, can be automatically calibrated

3.Computer automatic measurement image analysis, hardness software accurate correction and gradient diagram

4.Hardness is converted to other hardness according to national standard and ASTM; Hardness value statistics and hardness exceed alarm

5.Automatically generate test report, all test data will be saved forever, easy to historical query

Rockwell measurement software interface

Vickers measurement software interface

Brinell measurement software interface

III、Standard configuration:

| Name | Quantity | Name | Quantity |

| Desktop computer | 1 | Industrial camera | 1 |

| Blovey Software | 1 set | Dongles | 1 |

| floodlight | 1 set | Hardness blocks (HRC High block, HRC Low Block HRB, HBW2.5/187.5, HV30) | 5 blocks |

| Rockwell, Vickers diamond indenter | 1 each | Carbide ball indenter (diameter 1.5875, 2.5, 5mm) | 3 pieces |

| Micrometer eyepieces (15X) | 1 | Objective lens (2.5X, 5X) | 2 |

| Electric sliding test bench | 1 | Large, medium, and V-shaped test stands | 1 each |

| Flash drive | 1 | Level | 1 |

| Dust bag | 1 | Power cord | 1 |

| Product certificate, warranty card | 1 copy | Instructions | 1 copy |