TMHR-150XYZ Automatic Rockwell Hardness Tester

1. Product Description

1) Measure all Rockwell and surface Rockwell scales

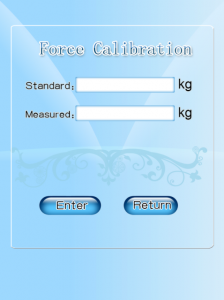

2) Test forces are automatically corrected according to standard dynamometers.

3) The Z axis of the worktable rises and falls automatically, and the X and Y axes of the sample table move automatically.

4) Press the start button, the table rises automatically, the sample touches the indenter after automatic loading, automatic unloading, automatic display hardness value.

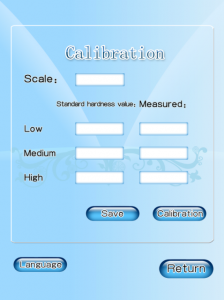

5) According to the standard hardness block, each hardness scale is divided into high, middle and low three sections for automatic correction.

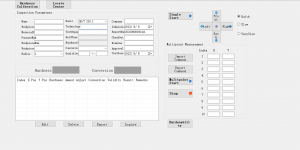

6) Measure any point on any sample in the range of 100 mm *200 mm.

7) Set measuring point, multi-point automatic testing, batch testing, greatly improve the efficiency.

8) All kinds of fixtures can be customized for batch testing of different samples.

9) Powerful data processing function, including: HR, HB, HV and other hardness conversion, set the qualified range, overlimit automatic alarm, can be input tester, sample name and other information.

10) When the host machine is used independently, the data USB disk is directly saved as EXCEL format, which is convenient for editing and processing.

11) The system has its own database, the measured parameters and data are automatically saved to the database.

12)Product design and production, with independent intellectual property rights and software copyright, can be customized and long-term software upgrade.

2. Technical parameters:

| Model | TMHR-150XYZ |

| Rockwell initial test force | 10 KGF (98.07 N) |

| Superficial Rockwell initial test force | 3.0 KGF (29.4 N) |

| Rockwell total test force | 60kgf(588N) 100kgf(980N) 150kgf(1471N) |

| Surface Rockwell total test force | 15kgf(147.1N) 30kgf(249.2N) 45kgf(441.3N) |

| Rockwell hardness scale | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRR, HRP, HRS, HRV |

| Surface Rockwell hardness scale | 15N, 15T, 15W, 15X, 15Y, 30N, 30T, 30W, 30X, 45N, 45T, 45W, 45X, 45Y |

| Rockwell test range | HRA:20-88, HRB:20-100, HRC:20-70, HRD:40-77, HRE:70-100, HRF:60-100, HRG:30-94, HRH:80-100, HRK:40-100, HRL:100-120 HRM: 85-115, the HRR: 114-125 |

| Surface Rothschild test range | HR15N: 70-94 HR30N: 42-86 HR45N: 20-77

HR15T: 67-93 HR30T: 29-82 HR45T: 1-72 |

| Meet standard | BSEN 6508, ISO 6508, ASTM E18, GB/T230 |

| Dwell time | 0-99s |

| Hardness resolution | 0.1 HR |

| Error of test force | < 0.5% |

| Data output | LCD display |

| Data store | The measurements are saved on a USB flash drive in EXCEL format |

| Conversion scale | Lowe’s, Brucellae, Vickers |

| Maximum allowable specimen height | For ordinary sample table, 300mm;With X mobile station, 200mm; 100mm for X/Y moving station |

| Distance from indenter to machine wall | 200mm |

| Size | 560 * 280 * 850 mm |

| Weight | 80kg |

| Power supply | AC220 + 5%, 50 ~ 60 hz |

3. Operation interface

4. Software interface

5. Standard accessories:

|

Item |

quantity |

Item |

Quantity |

| Diamond Rockwell indenter |

1 - |

Diameter 1.5875mm ball indenter |

1 - |

| Hardness blocks (HRC high and low, HRB, HR15N, HR30N, HR30T) |

Each one |

Large, medium and V-shaped test tables |

Each one |

| Computer |

1 |

X/Y Precision motor moving working table |

1 |

| Power cord |

1 the root |

USB disk, touch pen |

Each one |

| Product certificate, warranty card |

1 |

Instructions |

1 |