TMP-10 &TMP-20 Automatic Grinding-Polishing Machine

- Product Features

- 6 samples, pressurized independently.

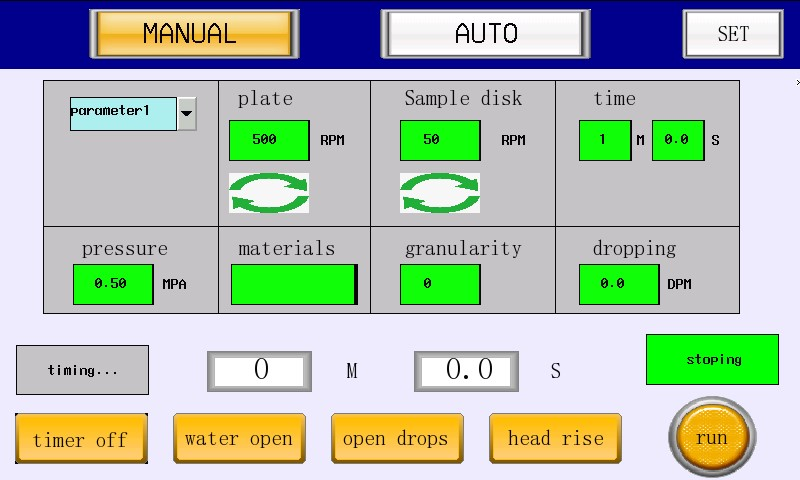

- PLC independently controls the grinding disc and sample disc: all grinding parameters, such as speed, grinding time, rotation direction, water valve closing, etc., are automatically saved and easily invoked.

- Touch screen interface: easy to set grinding parameters, intuitive state display, simple operation.

- The rotation of grinding disc and sample disc is infinitely variable, and the rotation direction can be switched.

- PLC controls the on and off of the water and abrasive drip.

- Working mode:

1) Automatic mode:

According to the sample material or user's habit, can set and call: 30 sets of process (process), each set of process can contain 10 steps of process parameters (each process for a certain step of grinding or throwing process process parameters: rotation speed of grinding disc and grinding head, grinding and throwing time.)

2) Manual mode:

According to each step of grinding and throwing process, 30 process parameters can be set and called: rotation speed of grinding disc and grinding head, grinding and throwing time, water on and off.

3) Setting mode:

To operate a function of a device independently

- Easily replace the magnetic anti-sticking disk, you can complete the coarse, fine grinding and coarse, fine polishing of all kinds of samples, a disk is equivalent to N disks.

- Electromagnetic automatic locking brake, instead of manual grinding head locking wrench, more convenient.

- U disk store 300 process, can be imported and exported.

- Chinese/English interface switch.

- High precision, smooth operation, low noise.

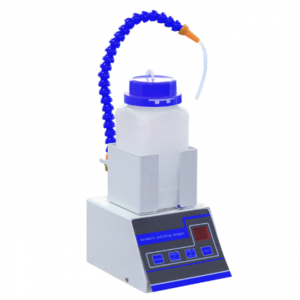

- Optional drip dispenser.

- Optional mobile remote control operation module.

- Technical Specifications

|

Item |

TMP-10 |

TMP-20 |

|

Station |

Single disc |

Double disc |

| Working disc diameter | standardφ254mm( optionalφ230mm、φ203mm)with magnetic switchboard system | |

| Rotate speed | 50-1000r/min The forward and backward rotation can be switched | |

| Grinding head speed | 30-200r/min | |

| Manual mode | can select 30 sets of parameters, each set set and called separately | |

| Automatic mode | 30 sets of process (process), each set of process contains 10 steps of process parameters (from process 1 to process 10 automatically, each step has an independent set of parameters) | |

| Sample holder | 30mm can be 6 holes (optional 20mm 6 holes, 40mm, 50mm 3 holes, others can be customized) | |

| Grinding head locking mode | Electromagnetic automatic lock | |

| Working air source pressure range | More than 0.6MPa | |

| Motor power | 0.75Kw | |

| Input voltage | AC220V,50/60Hz,2KW | |

| Dimensions | 700 x 730 x 350mm | |

| Weight | 74kg | |

- Standard Accessories

|

Item |

Quantity |

Item |

Quantity |

|

input-water pipe 8mm |

1 |

output-water pipe 25mm |

1 |

|

4-point filter (60 mesh, double layer) |

4 |

Rubber pad with strainer |

1 |

|

Hose hoops |

1 |

Triangle valve |

1 |

|

Fast twist joint |

1 |

Teflon tape |

1 |

|

waterproof ring |

2 |

hook |

1 |

|

Data cable |

1 |

Power cable |

1 |

|

Touch pen |

1 |

Instruction manual machine certification |

1 each |

|

Diamond polishing liquid,6micron,200ml |

1 |

Anti-sticky disc(250mm) |

2 |

|

One side sticky grinding paper(250 mm) 180#、320#、600#、1000# |

2 each |

Polished cloth (with glue, 250mm) Flocking (brown), canvas |

1 each |

2.Optional Accessories

| Metallographic grinding paper | GSC250A |

|

| Anti-sticky disc | MAGNOMET |

|

| Polishing cloth | FT250A |

|

| Diamond grinding and polishing liquid | DSU |

|