TMP-10X &TMP-20X Fully automatic metallographic grinding and polishing machine (center pressure)

I、 Product Features

- Center loading force mode, fixed six samples at one time, complete the whole grinding and polishing process, to ensure that the grinding throws out the complete plane of each sample

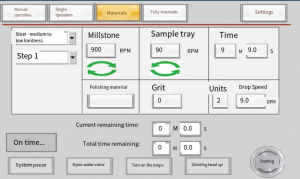

- Grinding disc and sample disc: set and run speed, grinding time, rotation direction, water valve closed all grinding and polishing parameters, and automatically save, easy to call;

- PLC + 1KW high power servo motor, 1KW high power servo motor (2*1KW optional) torque, regardless of speed, torque is large and constant;

- Wide speed range, from 0 RPM to 1000 RPM (Max. 1500 RPM);

- The turntable quickly starts and stops, and the turntable can stop rotating in 2 seconds;

- Speed, grinding and polishing time, rotation direction, water valve closed all grinding and polishing parameters, and automatically save, easy to call;

- Imported PLC brand, reliable quality;

- Touch screen interface, easy to set grinding and polishing parameters;

- 4 working modes:

1) Fully automatic mode:

According to the sample material or user's habits, can be set and called: 99 sets of process (process), each process can contain 10 steps of process parameters (each process for a certain step grinding or polishing process parameters: grinding disk and grinding head rotation speed, grinding and polishing time......)

2) Single process mode:

According to each step of grinding and polishing process, 30 kinds of process parameters can be set and called: grinding disk and grinding head rotation speed, grinding and polishing time, water off...

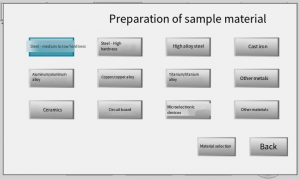

3) According to the material mode of preparation:

According to the type of sample material, select the corresponding grinding and polishing process parameters

4) Manual mode:

For a function of the device, operate separately

10.Comes with 4 or 6 channel automatic drip device (optional):

1) The main machine of the grinding and throwing machine controls the four-channel drip device, and the drip variety and speed are issued by the grinding and throwing machine

2) The drip dispenser has three working modes: manual, on-line and fully automatic

3) Connect with the polishing machine, according to the grinding and polishing parameters set by the grinding and polishing machine to drop liquid; Each mode can be set independently: drip speed, drip time

11.Easily replace the magnetic anti-stick disc, you can complete the rough, fine grinding and rough, fine polishing of all kinds of samples, a disc is equivalent to N disks;

12.Chinese/English interface switch;

13.Mobile remote control operation (optional)

14.The loading force can be adjusted on the fly for flexibility and convenience.

15.By using the solenoid valve to control the water on and off.

16.Sample grinding layer thickness control: accurately control the amount of sample grinding, grinding to the specified position (optional);

17.External dropper control: drop speed and drop material of external dropper (optional);

Technical parameter

| Specifications | TMP-10X | TMP-20X | |||

| Station | Single plate | Double platter | |||

| Loading force mode | Center loading | ||||

| Mill diameter | Standard φ254mm (optional φ230mm, φ203mm) with magnetic transfer disk system | ||||

| Grinding disk speed | 0-1500 RPM forward and reverse steering can be switched | ||||

| Sample disk speed | 30-200 RPM steering forward and backward can be switched | ||||

| Sample Tray | Standard with φ30mm six holes(Optional φ20 six holes, φ40 six holes, φ50mm three holes, the rest can be customized) | ||||

| Loading force range | 30-200N | ||||

| Manual mode | 30 sets of parameters can be selected, each set and called separately | ||||

| Automatic mode | 99 sets of process (flow), each set of process contains 10 steps of process parameters(Automatically from process 1 to process 10, each process has an independent set of parameters) | ||||

| Motor power | 1KW | 1KW (2*1KW optional) | |||

| Power supply | AC220V, 50/60Hz, 2KW | ||||

| Overall dimensions (L * W * H) | 760 x 470 x 700 | 760 x 730 x 700 | |||

| Weight | 90kg | 120kg | |||

III、Standard accessories

| Name | Quantity Single/double plate | Name | Quantity Single/double plate |

| Waterproof ring | 1 /2 | Gripper | 1 set |

| Data adapter cables | 1 | Power adapter cable | A root |

| Mounting table | 1 | Stylus pen | 1 |

| Sandpaper with glue (250) 320# | 10 sheets | Sandpaper with glue (250) 1000# | 10 sheets |

| Polished cloth velvet with back glue (250) | 1 sheet | Diamond suspended polishing liquid 6 microns 200ml | 1 bottle |

| Anti-stick dish (250mm) | 1 /2 sheets | With magnetic work plate (250mm) | 1 sheet /2 sheets |

| Buffing Lubricant coolant Blue 200ml | 1 bottle | Anti-stick tray pry bar (for anti-stick tray placement and prying up) | 1 |

| Technical documents: 1, user manual 2, product certificate | One copy of each. |

Options

- Sample grinding off layer thickness control module: resolution accuracy 0.01 mm

- Four channel automatic drip device

- Mobile terminal remote control operation module

- Common consumables:

| MAGNOMET | Anti-stick tray 5 pieces/box Diameter: Φ250mmThe surface is coated with special anti-stick coating, and the sandpaper or polishing cloth with adhesive backing can be pasted on this disk, which is easy to change and leaves no residual glue. It can be used repeatedly.

The disc is used directly on magnetic discs from BUEHLER or STRUERS; Replacement of BUEHLER's MagnoMet and MagnoPad |

| GSC250A | Metallographic sandpaper 100 pieces/packetAbrasive: black silicon carbide

Particle size: P80# 120# 180 # 320 # 600 # 800 # 1000 # 1200 # 1500 # 2000 # Size: Φ250mm water resistant With pasted back, the sandpaper can be fixed directly to the mill |

| FT250A | 10 pieces/bag of metallographic polishing fabricVelvet (long pile)/canvas (short pile)/cloth (short pile)/silk (no pile) Φ250mm

Pasted back: The fabric can be fixed directly to the mill |

| DSU | Diamond suspension grinding polish 500ml/ bottleThe diamond is suspended in the liquid and evenly distributed by watering can or automatic drip

Particle size: 0.25, 0.5, 1, 1.5, 2.5, 3, 3.5, 5, 6, 7, 9, 10, 14, 15, 20, 28, 40 microns for a variety of materials |