Tmteck Coating Thickness Gauge TM260 with Built-in Printer

Portable Digital Coating Thickness Gauge TM260 adopts two thickness-measuring methods: magnetic induction (ferrous) and eddy current (non-ferrous). It can rapidly, nondestructively, and precisely measure the thickness of non-magnetic coating on magnetic metal substrate, and the thickness of non-conductive coating on non-magnetic metal substrate. This paint meter can be equipped with 6 optional probes for different applications. It is suitable for both field testing and laboratory research.

Product Details

Features

- ● Two operation principles are adapted: magnetic induction (ferrous) and eddy current (non-ferrous) to take non-destructive measurements

- ● 6 types of probes are available for different applications

- ● Features two working modes: DIRECT and BATCH& two measuring ways: CONTINUE and SINGLE

- ● Statistics include the mean, maximum, minimum, test numbers and standard deviation.

- ● Memory of 500 data

- ● Two calibration methods for better correction

- ● Integrated with printer to print the statists values if needed

- ● Low battery indication and error alarm

- ● Backlight for the screen

- ● Auto or manual shutdown

- ● Conform to the standards of DIN, ISO, ASTMBS.

| Standard Delivery | |

| Main unit | 1 |

| Probe | 1 |

| Substrate | 1 |

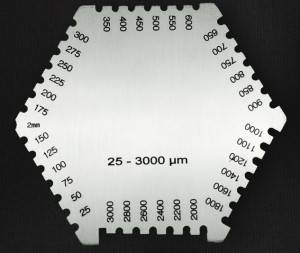

| Calibration foil | 1 |

| Charger | 1 |

| Printing paper | 1 |

| certificate | 1 |

| Warranty card | 1 |

| Instruction manual | 1 |

Specification

| Probe types | F | N | |

| Measuring methods | magnetic induction | eddy current | |

| Measuring range | 0 ~1250 μm | 0 ~1250 μm, 0 to 40μm(for chrome plate on copper) | |

| Minimum resolution | 0.1μm | ||

| Tolerance | Zero point calibration | ±(3%H+1)μm | ± (3%H+1.5)μm |

| H means the thickness of tested piece | |||

| Two points calibration | ±[(1~3)%H+1]μm | ±[(1~3)%H+1.5]μm | |

| H means the thickness of tested piece | |||

| Measuring condition | Min. curvature radius (mm) | Convexity 1.5 | Convexity 3 |

| Min. testing area diameter (mm) | Ø7 | Ø5 | |

| Critical thickness of substrate(mm) | 0.5 | 0.3 | |

| Standards | DIN,ISO,ASTM,BS | ||

| Calibration | Zero and foil calibration | ||

| Interface | USB2.0 | ||

| Statistic | Number of measurement, mean,standarddeviation, maximum and minimum | ||

| Data memory | 500 readings | ||

| Limits | Adjustable with alarm | ||

| Power | Li rechargeable battery | ||

| Operating environment | Temperature: 0~40℃ | ||

| Humidity: 20%~90% | |||

| No strong magnetic field | |||

| Dimensions (mm) | 215×84×42 | ||

Optional Probes and Application Guide

| Probe model | F400 | F1 | F1/90º | F10 | N1 | F5 | |

| Operatingprinciple | Magnetic induction | Eddy current | |||||

| Measuring range (µm) | 0-400 | 0-1250 | 0-10000 | 0 to 1250 μm 0 to 40μm (for chrome plate on copper) |

0-1250 | ||

| Low range resolution (µm) | 0.1 | 0.1 | 10 | 0.1 | 0.1 | ||

| Accuracy | One-pointcalibration (µm) | ±(3%H+1) | ±(3%H+10) | ±(3%H+1.5) | ±(3%H+1) | ||

| Two-pointcalibration (µm) | ±[(1~3)H%+0.7] | ±[(1~3)H%+1] | ±[(1~3)%H+10] | ±[(1~3)%H+1.5] | - | ||

| Measuring conditions | Min curvature of the min area (mm) | Convex 1 | 1.5 | Flatten | 10 | 3 | Angle |

| Diameter of the min area (mm) | φ3 | φ7 | φ7 | φ40 | φ5 | φ7 | |

| Critical thickness of substrate (mm) | 0.2 | 0.5 | 0.5 | 2 | 0.3 | 0.5 | |

Write your message here and send it to us