TMTECK Digital Eddy Current Detector TMD-302

Technical Parameters

Basic Specification

|

Operation interface |

Touch Screen, Shuttle digital Knob panel |

|

Frequency range |

100Hz-3MHz(Enhanced model 100Hz-6MHz ).

The Minimum increment is 1% of indicated value. |

|

Gain |

0-100db. Minimum increment is 0.1db.

Horizontal and Vertical gain can be adjusted individually or together |

|

Sensitivity |

200V/Ω adjustable |

|

Digital Rate |

10-1500 times/sec |

|

Phase Rotation |

0-360°(step 1°) |

|

Scan |

0.001-9.999s adjustable. Minimum increment is 0.001s |

|

Low-pass filtering |

0-500 Hz. Minimum increment is 1Hz |

|

High-pass filtering |

2-499 Hz. Minimum increment is 1Hz |

|

Zero setting |

Manual forced zeroing, minimum response time<0.1 s |

|

Screen Display |

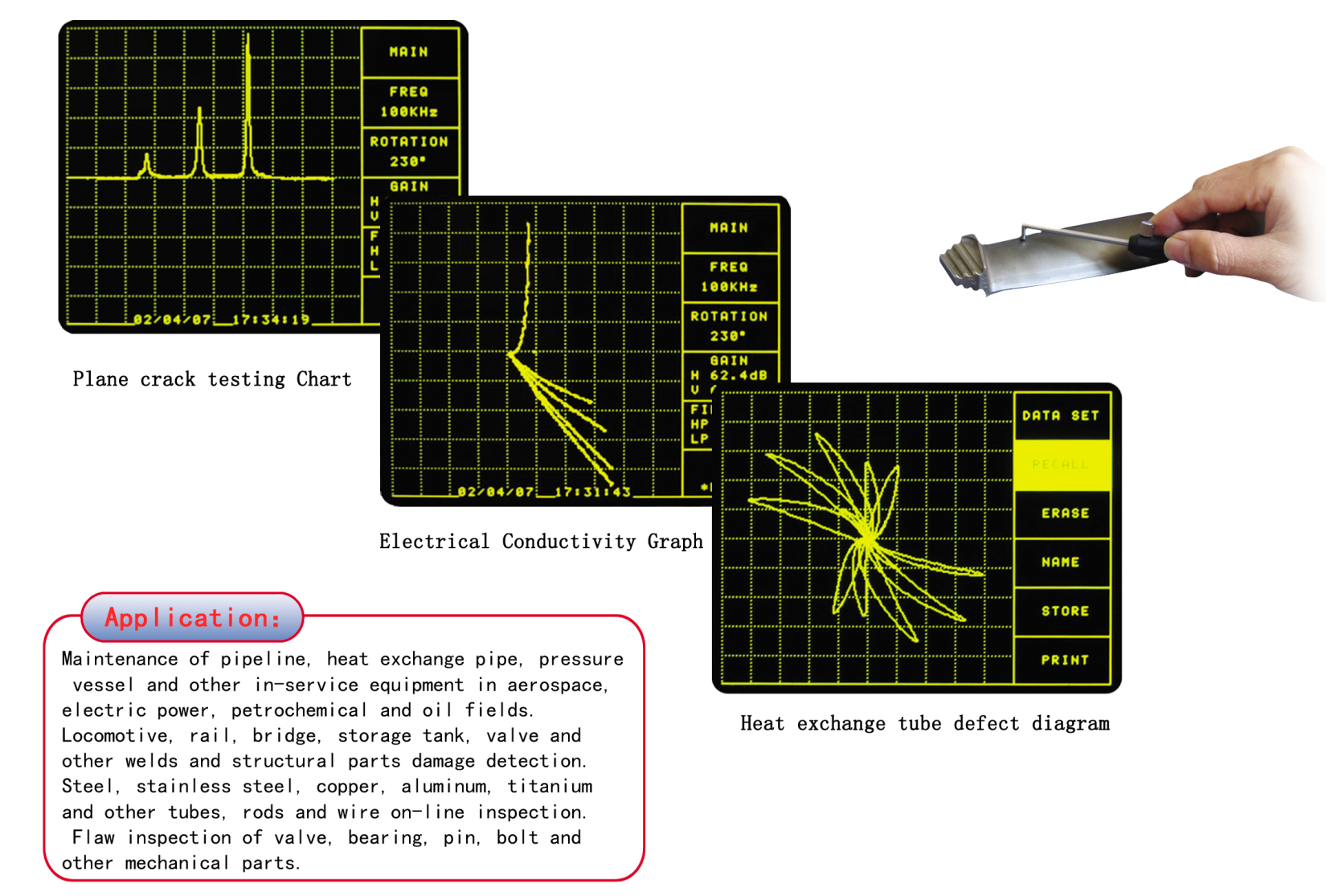

Eddy current signal impedance diagram display |

| Eddy current signal time base scanning curve display | |

| Simulated 3D stereogram display | |

|

Screen Retention time: |

The retention time of impedance trace is optional from 0.1 to 20s, step 0.1s |

|

Scan track retention time is equal to one screen cycle |

|

|

The eddy current signal track is permanently retained and can be manually cleared |

|

|

Signal analysis |

Automatic or manual phase measurement |

|

Probe Driving |

It is divided into 12 levels, and the peak-to-peak voltage is adjustable from 1V to 12V |

|

Probe Type: |

Bridge Type, Reflective, Absolute, Differential |

|

Pen Type, Surrounding, Penetrating, saddle type, bolted type,sliding type, various point type, combined type |

|

|

Optional probe adapter, compatible with domestic and foreign manufacturers of all kinds of probes |

|

|

Alarm mode: |

Impedance flat display :1-4 size adjustable right Angle and polar alarm zone. |

|

Scan shows: two high and low adjustable alarm fields |

|

|

Program Storage: |

It can store and invoke 100 units of instrument Settings, including detection parameters, display control, alarm mode and coordinate background. Each program can be named with up to 17 characters.

Without charging, device setting information can still be retained for more than 10 years |

|

Data Storage: |

It can store and play back 20 units frozen and locked eddy-current signal impedance maps or all eddy-current signal impedance maps within 1 to 60s cycles. Each data can be named with up to 17 characters. |

| Real-time date and time display |

Input/output Interface

|

Charger Socket |

External AC charging adapter to charge the battery or provide power |

General Specification

|

Dimension |

200mm*120mm*100mm |

|

Weight |

1.5Kg (battery included) |

|

Display |

Works in strong light (5.7″ semi-reflective and semi-transparent LCD screen with backlight off ) |

Power supply

|

DC |

Lithium rechargeable battery, built-in intelligent charging protection circuit, fully charged can work for 8 hours without cut-off |

|

AC |

Outsourced Power supply 100-240VAC, 50/60 Hz |

The Difference Between TMTeck Portable Eddy-current Detector

|

TMD-301 |

TMD-302 |

TMD-306 |

|

| Wave Filter |

× |

√ |

√ |

| 3D scanning inspection |

× |

× |

√ |

Aviation

Surface inspection of aircraft components such as blade, wheel hub and landing gear

Rivet hole or bolt hole inner surface crack detection (fastener disassembly or not can be both easily detected)

Detection of inter-layer corrosion in composite materials, such as aircraft multi-layer structures, aluminum skin and fuselage wing joints

Detect the thickness changes of metal sheet due to wear and corrosion

Measurement of thickness of non-conductive coating on conductors or non-magnetic coating on ferromagnetic substrates

Conductivity testing of non-magnetic metals

Electric Power Industry

Detection of surface defects of metal components of turbine blades and pin holes

C scan (3D waterfall display) Flaw detection of the center hole of the large shaft of the steam turbine

Defect detection and thickness measurement of Condenser and other heat exchange tubes (such as brass, copper, titanium alloy, etc.)

Boiler tube defect inspection

Petrochemical Industry

Nondestructive testing and thickness measurement of Stainless steel tube of Heat exchanger

Nondestructive testing of Carbon steel tube of Heat exchanger

Nondestructive inspection of inner wall of furnace tube

Casing and sucker rod defect detection and material sorting

All kinds of metal pipeline, steel structure weld, crack inspection

Thickness measurement of Carbon steel container inner surface, stainless steel surfacing layer

Metallurgy and Machinery Industry

On-line eddy current inspection of carbon steel, stainless steel, titanium, copper, red copper, silver-copper, copper-coated aluminum and double-layer composite pipe and other metal tubes, rods and wires

On-line non-destructive inspection of Valve, bearing, pin, bolt, barrel, barrel and other mechanical parts

Standard Configuration

|

TMD-302 packing list |

||

|

No. |

Commodity Description |

Qty |

|

1 |

Eddy current detector |

1 |

|

2 |

Eddy current point-type probe |

1 |

|

3 |

Plate block |

1 |

|

4 |

12.6V power adapter |

1 |

|

5 |

Instrument Pack |

1 |

|

6 |

Operation Manual |

1 |

|

7 |

QuickStart Manual |

1 |

|

8 |

Quality certificate |

1 |

|

9 |

Warranty bill |

1 |