Ultrasonic flaw detector TFD800C PLUS

★ User friendly dialog interactive helps operations like Calibration, making curves, etc.

★ All tools you need: DAC, AVG, AWS, Weld diagram,etc.

★ Pulse Repeatition Frequency: 10-2000Hz precise adjust, high speed scan, no miss out.

★ High Signal to noise ratio, clear and stable echo, anti-noise design, perfect for tough working conditions.

★ 10-digit AD, high speed sampling leads to better echo diagram with all details. Sensitive and can detect even tiny flaws.

★ Crystal clear true-color display. Helpful user interface makes the operation much easier.

★Unlimited USB data storage.,PDF reports output.

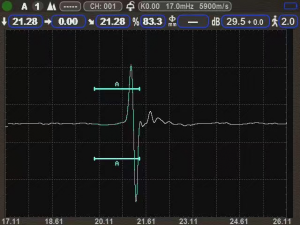

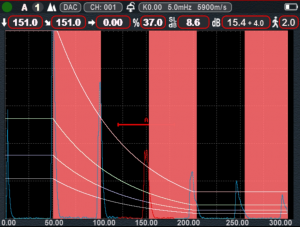

Main Interface Report

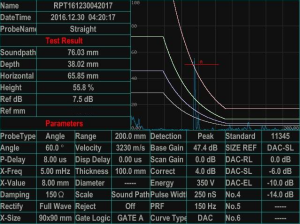

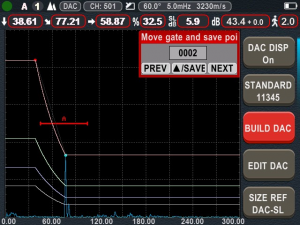

Making DAC Standards

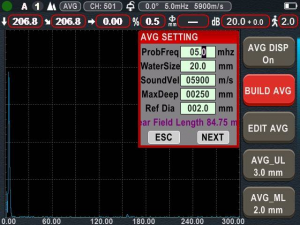

Coded Echo AVG

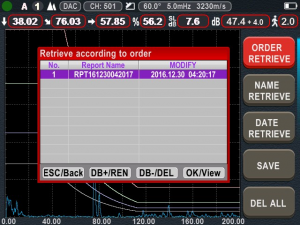

Report List

Specifications

- Range:0-10000 mm ,at steel velocity

- Material Velocity:1000~10000 m/s

- Pulse Repetition Frequency:10-2000Hz

- Dynamic range:≥38dB

- Linearity: Horizontal: +/-0.2% FSW, Vertical: 0.25% FSH, Amplifier Accuracy +/-1 dB.

- Resolving Power:>40dB (5P14)

- Sensitivity Leavings:>65dB

- Reject (suppression): 0 to 80% full screen height

- 500 independence setup, any criterion can be input freely, we can work in the scene without test block;

- Big memory of 1000 A graph

- Test Modes: Pulse echo, dual element and thru-transmission

- Probe Types: Single Straight, Single Angle,Daul Straight, Daul Anlge,Thrugh,Creeping,Surface

- Gate Monitors: Two independent gates controllable over entire sweep range

- Units: Inch or millimeter

- Power Requirements: AC Mains 100-240 VAC, 50-60 Hz

- Display Delay: -20 to 3400 µs

- Probe Delay/Zero Offset : 0 to 99.99µs

- Internal rechargeable Li-ion battery pack rated 7.2V at 5600 mAh

- 10 hours nominal operating time depending on display brightness

- 4 hours typical recharge time

- H×W×D(mm):240×170×38 (mm)

- Weight :1.0kg

- Operating Temperature: -10℃ to 50℃

- Storage Temperature: -30℃ to 50℃

- Pulse Energy: 200V, 300V, 400V, 500V selectable

- Rectification: Positive half wave, negative half wave, full wave, RF System

- Gate Monitors: Two independent gates controllable over entire sweep range

- Sensitivity:110 dB max in selectable resolution 0.1, 1.0, 2.0, 6.0 dB.

- Transducer Connections: BNC or LEMO

Functions

- Automated display precise flaw location(Depth d、level p、distance s、amplitude、sz dB、ф).

- Flaw sizing: Automatic flaw sizing using AVG/AVG or DAC, speeds reporting of defect acceptance or rejection.

- Automated calibration of transducer Zero-point, Angles, Front edge and material Velocity .

- Convenient to make and use DAC and AVG to evaluate the echo, the curve can be modified and compensated.

- Connectting U-disk,the unit can get unlimited memory,PDF reports out put and Upadte system.

- Weld diagram.

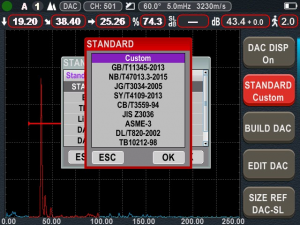

- There are 15 standards of in the unit.

- AWS D1.1.

- Curved Surface Correction feature.

- Crack Height Measure function.

- Magnify gate:spreading of the gate range over the entire screen width.

- Auto-gain function.

- Envelope: Simultaneous display of live A-scan at 60 Hz update rate and envelope of A-scan display.

- Peak Hold: Compare frozen peak waveforms to live A-Scans to easily interpret test results.

- Scan Freeze:Display freeze holds waveform and sound path data.

- Alarm:Beep and LED.

- Real Time Clock.

- Fill echo.

- Capture mark.

- Echo color within the Gate.

Base Instrument Package

- Portable Ultrasonic Flaw Detector

- Straight Beam Transducer (4 MHz, Φ10)

- Angle Beam Transducer (4 MHz, 8 mm×9 mm, 60°)

- Interconnect Cable for the transducer (Q9-C5,or optional C9- C5)

- Rechargeable Li-Ion Battery Package, 8 amp hour

- Power supply/charger unit

- Operating Manual in English

- App Software

- Strap