Ultrasonic thickness gaugeTM282 with A&B Scan/Through coating/Software

TM282 Series Color Screen with A/B-Scan Ultrasonic Thickness Gauge Professional in Solving Various Difficult Thickness Measurement

Features:

2.4” color OLED, 320 X 240 pixels, contrast 10,000:1

Live Color A-Scan

Users could directly see the color waveform of the ultrasonic sound (or A-scan) on the screen, which is quite important for the occasions that we need to check the correctness of the testing results. Many cases will cause wrong testing results or even noreadings. We could find the causes easily through the A-scan. Adjust the three parameters of GAIN, BLACKING, GATE, and then we will get the right readings.

Live Color B-Scan

TM282 series thickness gauge has time base B-scan function. Move the probe along the workpiece surface, then the cross -sectional profile of the workpiece display, use for observe the underside contour of the workpiece.It could be automatically capture a minimum value of the B-scan image, and indicate the position of the minimum by a red triangle. You can see any point thickness value of the B-scan image by moving the pointer.

Through Coating Function

No longer need to waste time to remove the coating

Now TM282D and TM282DL also have this widely acclaimed function. It's realized by measuring the two continuous bottom surface of the substrate. This mode also has more advantages:

1.Exempt Zero Calibration

2.High Stability, the measuring value is not influenced by the probe pressure, the coupling layer thickness and the surface dust of the workpiece.

3.Zero Drift

Power-Cutting Function

The Power-cutting button is added on the bottom.If you do not use the device for a long time,you can press this buttton to save the energy, which makes battery a much longer life.

More Practical Function

1.Difference/Reduction Rate: Difference mode displays the difference between the actual value and the normal value. Reduction rate calculates and shows the percentage of the thickness reduction when the material becomes thin. Typical application is to measure the metal material which is due to bending and becomes thin.

2.Max./Min. Capture: On this mode, the current thickness, minimum thickness and the maximum thickness will be shown on the screen at the same time.

3.Alarm Mode: Dynamic change the color of thickness readings when alarming.

4.Update Rate: Selectable 4Hz, 8hz and 16Hz. 4Hz for ordinary application, when you need a quick scan, such as high temperature measurement, you can choose higher update frequency.

5.Multi- Languages Available: Chinese, English, Japanese, French, German.

6.Echo to Echo: Measures the metal thickness only (ignore paint and coatings)

7.Data logger: 99999 thickness data logger with ID point in linear or grid files ( 400 files)

8.Output: USB 2.0 full speed connector. DataView report software

9.Size: 156mm) (L) 76mm) (W) x 1.25" (38 mm) (H)

10.Weight: 285 g

11.emperature: Gage Operating: -10° C to 50° C

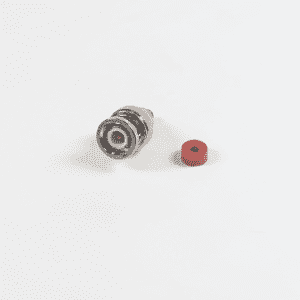

Standard TM510 Probe

The probe is the heart of the instrument,TMTeck has the world’s leading probe production technology. TM510 probe uses the high performance piezoelectric ceramic chip, with integrated metal die-casting shell, practical design of probe and cable separated, regardless of costs to create high quality .

The Difference Between TM282 Series Ultrasonic Thickness Gauge

| TM282 | TM282D | TM282DL | |

| Color Display | √ | √ | √ |

| Live A-Scan | √ | √ | √ |

| Time-based B-Scan | √ | √ | √ |

| Control of Gain and Gate | √ | √ | √ |

| Blanking | √ | √ | √ |

| Thru-paint&coatings | × | √ | √ |

| Data Logger | × | × | √ |

| DataView Software | × | × | √ |

Specifications of TM282DL Ultrasonic Thickness Gauge

|

Display Type |

2.4'' color OLED, 320×240 pixels, contrast 10,000:1 |

|

Operating Principle |

Pulse echo with dual elemet transducers |

|

Measuring Range |

0.50mm to 508mm(0.02'' to 20.00''), depending on material, probe and surface condition |

|

Measuring Resolution |

Selectable 0.01mm, 0.1mm(selectable 0.001'', 0.01'') |

|

Units |

Inch or Millimeter |

|

Rectify Mode |

RF+, RF-, HALF+, HALF-, FULL |

|

Display Mode |

Normal, Minimum/Maximum capture, DIFF/RR%, A-Scan, B-Scan |

|

V-Path Correction |

Automatic |

|

Update Rate |

Selectable 4Hz, 8Hz, 16Hz |

|

Material Velocity Range |

500 to 9999m/s(0.0197 to 0.3939 in/μs) |

|

Languages |

English, French, German, Japanese,Chinese |

|

Alarm Settings |

Minimum and Maximum alarms. Range of 0.25mm to 508mm (0.010'' to 20.00''). Dynamic waveform color change on alarm |

|

Power Requirements |

2 AA size batteries |

|

Operating Time |

Approximately 40 hours |

|

Instrument Shut-off |

Selectable ALWAYS ON or AUTO OFF after 5, 10, 20 minutes of inactivity |

|

Operating Temperature |

-10℃ to +50℃(+10°F to +12°F ) |

|

Size |

156mm × 75mm × 38mm (H × W × D) |

|

Weight |

270g including batteries |

Standard Delivery

|

Name |

Quantity |

|

Main body |

1 |

|

Probe |

1 |

|

Battery |

1 |

|

Couplant |

1 |

|

Carrying Case |

1 |

|

Operating Manual |

1 |

|

USB Cable |

1 |

|

Software |

1 |