wire rope flaw detector TMWR-300

One, product introduction

◆ can online testing of wire rope and wire breaking, wear, corrosion,deformation, loose strands, jump wire, material and other defects functionchanges.

◆The test results of the report can meet different industry standard also has the form of broken wires and the number of broken wires fault area and total basal area of the steel ratio of the display.

◆ using computer USB interface direct sampling analysis, with onlineacousto-optic alarm and real-time results function.

◆ sensor circular structure, circumferential surround, axial magnetization,the wire rope instant magnetization to saturation.

◆ sensing Chuai using alloy aluminum housing, waterproof, dustproof,shockproof, moisture-proof function.

◆ steady work, reliable performance, high precision, strong anti-interference ability, data accuracy.

◆ The software adapts to the Windows98 / 2000 / XP / Vista/windows7computer operating system.

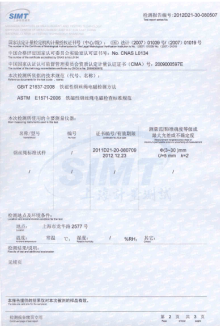

◆ According to the provisions of the state measurement and the state production safety law, each instrument by the national metrology institutes, according to USA ASTM1571 American standard as the third party inspection, and issue the test report, obtain legal qualification.

◆It is widely used in mines, ropeway, lifting equipment, elevator, port machinery, cable bridge etc.

Two, the core technology and legal qualification

1 virtual instruments: wire rope infinite uncertainty. Only the application of virtual instrument technology, replacing the traditional instruments with software, directly sampled and processed by the computer, so as not tomiss, not false, like watching movies, full scan of the steel wire rope, the result is accurate, repeatable.

2 three instruments: according to the regulations of wire rope in different sectors of the scrapping of the national standards, the productapplication of qualitative, quantitative, electromagnetic positioning, onlinenondestructive testing of wire rope broken wires, internal and externalcorrosion, abrasion, metallic cross-sectional area changes, loose strands,jump wire, deformation, material anomalies such as defects.

3 legal instruments: according to the regulations of the statemeasurement and the state production safety law, each instrument by thenational metrology institutes, according to USA ASTM1571-2006 Americastandard and GB/T21387-2008 as the third party inspection, and issue the test report, obtain legal qualification.

Three, technical indicators

◆The whole series of testing of wire rope diameter range: diameter 1.5 - 300 mm (need to configure different series specifications sensor).

◆The sensor and the wire rope relative speed: 0 - 6 m/s best: 0.3 - 1.5 m/s.

◆The guide sleeve and the gap sensor wire rope best: 2 - 6 mm, allowing the gap: 0 - 15mm.

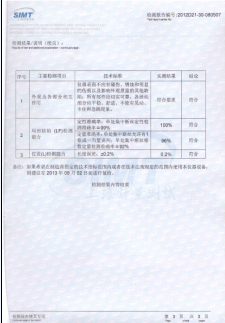

Broken wire defect (LF) detection capability

◆ Qualitative: single concentration of broken wire detection accuracy rate of 99%.

◆Quantitative: single concentration of broken wires number allowed a rootor an equivalent root misjudgment.

◆Single concentration of broken wires number no more than 100 times the error detection accuracy is greater than or equal to 92%.

Quantitative change rate of metallic cross-sectional area(LMA)

◆The sensitivity of detection repeatability error: ± 0.055%.

◆The detection precision indication permissible error: ± 0.2%.

◆Position (L) detection capability: percentage error are shown to detectlength: + 0.2%.

◆Power supply: battery powered 5V.

◆Sensor weight: common specifications < 10kg.

◆Environment temperature: -10 ℃ ~40 ℃, relative humidity: atmosphericpressure: 86~106Kpa ≤ 85%.

Four, the system configuration and type

1 wire rope diameter 8-54mm

2 wire rope flaw detector general computer model for type

|

Name |

Serial number |

Content |

Number |

Remarks |

|

The sensing unit |

1 |

(8-54mm) sensor | 1 | 8-54mm on-demand allocation |

|

The conversion unit |

2 |

RADF digital converter | 1 | Online monitoring, real-time alarm |

|

3 |

The 8344 signal transfer line | 1 | (or9355) | |

|

4 |

USB transmission line | 1 | ||

|

The processing unit |

5 |

V3.0 processing software package | 1 | |

|

6 |

Notebook computer | 1 | ||

|

Annex |

7 |

Standard packing box | 1 | |

|

8 |

Safety cable | 1 | ||

|

9 |

Packing list | 1 | ||

|

10 |

Product specification | 1 | (certificate, test report) | |

|

11 |

Issued by the national metrology institutes of third party test repor | 1 | Instrumentation has legal qualification |

The report style

The use of the customer